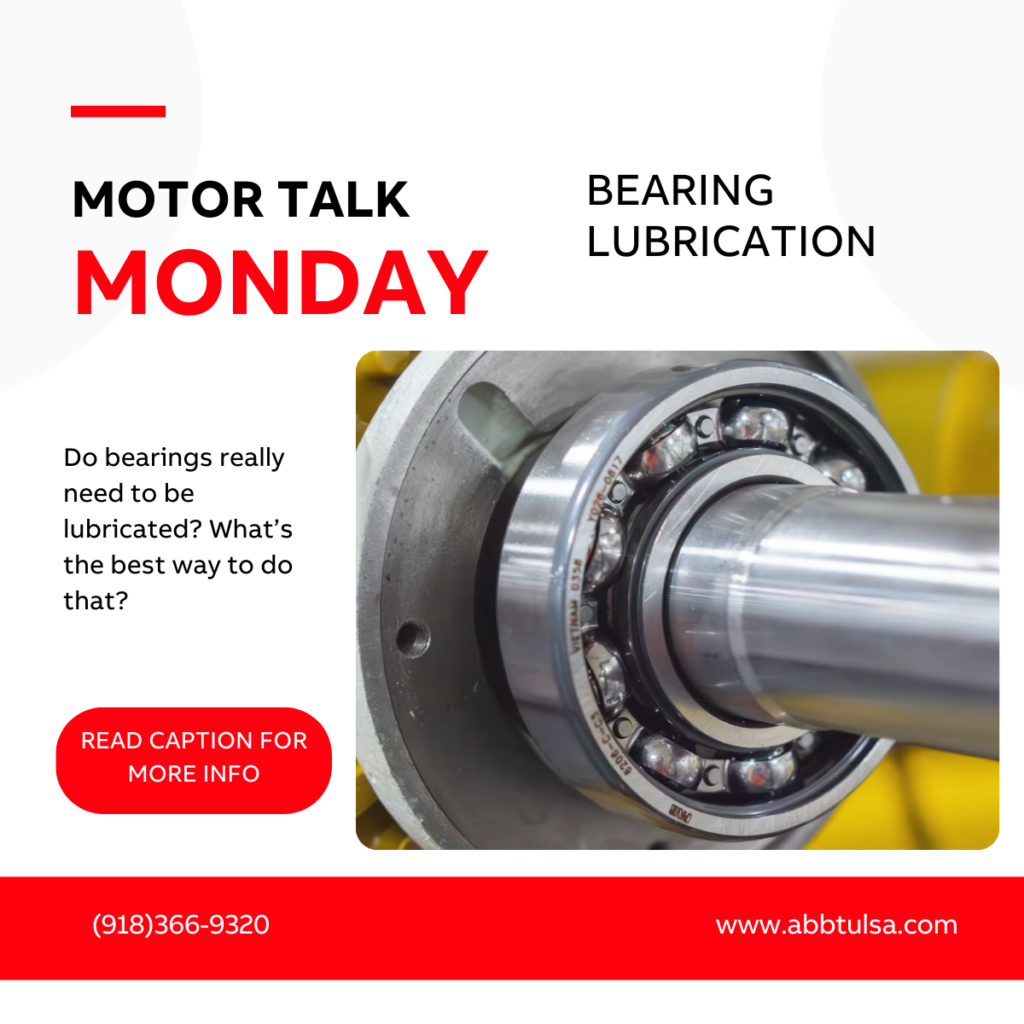

#MotorTalkMonday – bearing lubrication

Lubricating industrial electric motor bearings is crucial for maintaining the motor’s performance, reliability, and longevity. Here are the key reasons why this is important:

1. Reduces Friction and Wear

2. Dissipates Heat

3. Prevents Corrosion

4. Enhances Efficiency

5. Minimizes Noise and Vibration

6. Extends Equipment Life

7. Prevents Seizure

Best Practices for Lubricating Bearings:

• Use the Right Lubricant: Select the lubricant specified by the manufacturer based on the operating conditions.

• Proper Quantity: Over-lubrication can be as harmful as under-lubrication. Follow the manufacturer’s guidelines for the amount.

• Regular Maintenance: Implement a lubrication schedule based on the motor’s operational demands and environmental conditions.

• Cleanliness: Ensure the lubrication process is clean to avoid introducing contaminants into the bearing.

Proper lubrication not only ensures the motor operates efficiently but also prevents costly repairs and downtime, making it an essential maintenance task.

Interested in learning more? Watch the video below!