How can an electric propulsion system save 1,000,000 tons of fuel and contribute to a more sustainable future? How does a cable tie developed in 1958 contribute to the latest Mars expedition? And what does the monitoring of industrial motors have in common with a conventional fitness tracker? Here, we take you through some of the most interesting facts and trivia of our company’s portfolio – with short, easy to understand explanations.

ABB Motion Services

Did you know…

… the energy efficiency of industrial operations can be improved with digital solutions?

Energy efficiency is a strategic priority for many industries for all the right reasons. The rise of electricity prices paired with scared resources and the need to reduce carbon emissions and pollution have put energy efficiency at the top of the list of many global and local regulations as well as industry leaders.

Ensuring that the motors that power industry run as efficiently as possible is more important than ever. If roughly all the 300 million industrial electric motor systems in active service today were replaced with higher-efficiency models, global electricity consumption could be reduced by up to 10 percent with potential energy savings of 800 TWh/year, which is the equivalent of the electricity consumed by the UK, Spain and Italy combined in a year1.

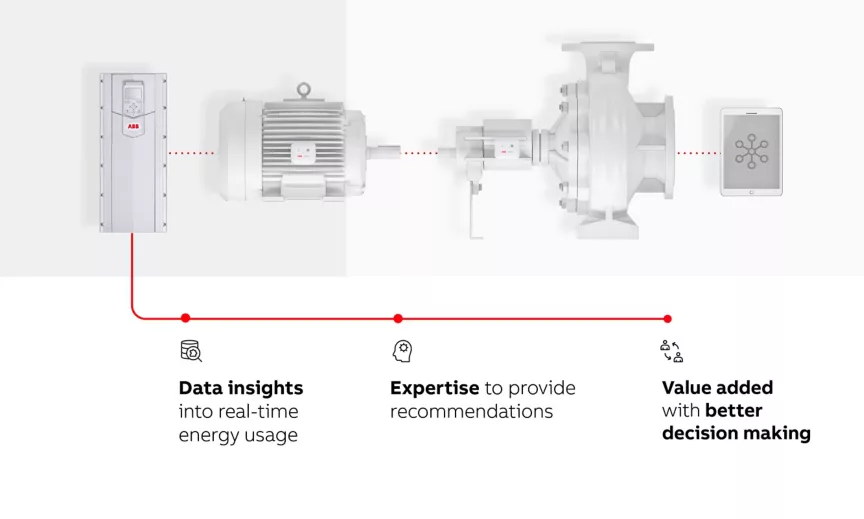

These are not negligible numbers and these savings can be made possible with the help of data insights and expertise delivered through the ABB Ability™ Digital Powertrain Energy Appraisal. This new service delivers a detailed report showing potential energy consumption optimization and carbon emissions reductions, all while lowering operational costs. The report empowers the operator to make better decisions regarding which motors to replace and or correctly scale for improved energy efficiency.

Waggeryd Cell, a Swedish pulp producer, has been one of the early adopters of this digital solution, which provided the information needed to identify the motors with low operating efficiency, as well as other motors that were wrongly dimensioned and thus underutilized, contributing to waste of energy.

By installing the ABB Ability™ Condition Monitoring solution, enabled by 156 smart sensors, the company was able to digitalize an entire critical production line. One year later, Waggeryd also utilizied the ABB Ability™ Digital Powertrain Energy Appraisal to provide ways to extract even further energy savings as the mill improved its reliability and availability.

Key facts:

- data insights into real-time energy usage

- expertise to provide recommendations

- value added with better decision making

Discover more about ABB Motion Services

Read the Waggeryd Cell success story

1World Power consumption | Electricity consumption | Enerdata